BULOVA 214 SPACEVIEW ACCUTRON 1960

As we all know it was Lip and Elgin who started the race for the Electric wristwatch by introducing their joint prototype in 1952. This race encouraged other manufacturers to come along and in result Bulova began their research in this field. Hamilton was first with the "unfinished" 500 calibre but Bulova was soon to make a giant step and turn the "Electric" obsolete overnight. The company put their entire trust in one ingenious engineer Max Hetzel from their plant in Switzerland. He was convinced that a tuning fork concept will be the most precise solution and so he managed to create a few prototypes already by 1955. Further research was transferred to the USA where Hetzel coordinated team efforts with William Bennett to develope a production sample.

Work continued... we have to remember that both miniature transistors and button batteries were being invented at that same time by various manufacturers around the World (use cell 387S=394 with plastic spacer). Finally in October of 1960 with plenty of support and enthusiasm from the management, the Bulova 214 Accutron was launched to market. Some models called "Spaceview" had an exposed movement to show the breakthrough space technology behind the success of the Accutron. These space versions sold in various case styles must have been very appealing to gadget oriented people... the green plastic must have been deliberately chosen as perfect contrast with the red copper wires of the coils. To underline the extreme precision of the Accutron the watch lacked a crown and had a setting lever hidden on the caseback.

Work continued... we have to remember that both miniature transistors and button batteries were being invented at that same time by various manufacturers around the World (use cell 387S=394 with plastic spacer). Finally in October of 1960 with plenty of support and enthusiasm from the management, the Bulova 214 Accutron was launched to market. Some models called "Spaceview" had an exposed movement to show the breakthrough space technology behind the success of the Accutron. These space versions sold in various case styles must have been very appealing to gadget oriented people... the green plastic must have been deliberately chosen as perfect contrast with the red copper wires of the coils. To underline the extreme precision of the Accutron the watch lacked a crown and had a setting lever hidden on the caseback.

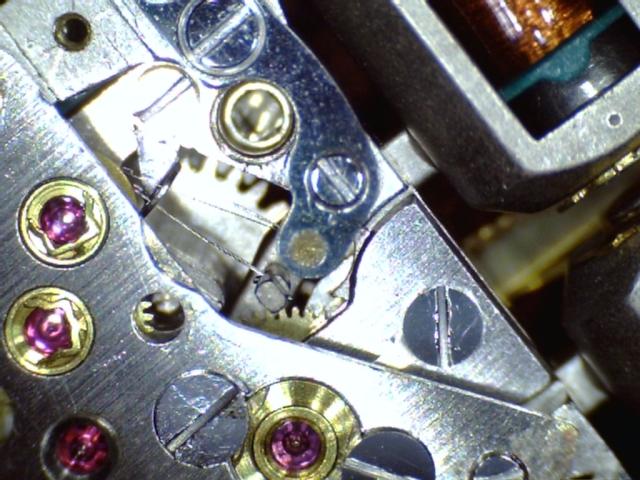

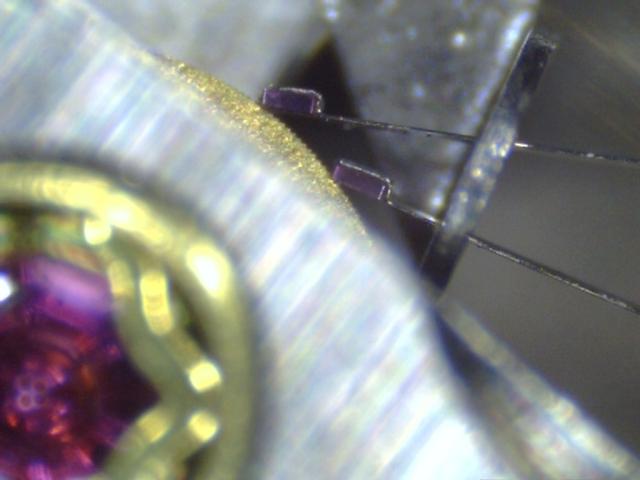

The Accutron principle is pretty simple - a battery activates the electronic circuit where a transistor is responsible for further "on-off" communication with both electromagnetic coils. The coils activate the permanently magnetized "cups" of the tuning fork which result in constant 360Hz audible "humming" vibrations. A tiny steel wire called "index finger" (mounted onto the vibrating fork) transmits it's motion to the mechanical gear train starting with an index wheel containing 300 tiny teeth unvisible to a naked eye. To improve reliability the index finger and an additional countering pawl finger (fixed on the movement plate) are tipped with tiny ruby jewels. The pawl finger prevents backlash on the return draw of the index finger and must be properly adjusted (indexed) against the index wheel to provide sufficient torque.

In the event of finding a nonworking Accutron a highly probable cause is the coil assembly that will need to be exchanged completely (unless you know how to check a bad transistor). Insufficient torque on the index wheel is the second most common issue with nonworking Accutrons. They will produce the audible hum but improper allignment of the fingers will not move the gear train. Proper adjustment of the pawl finger against the index wheel is called "indexing" and is achieved by turning a screw on the pawl post. Due to the microscopic size of these parts the best results are achieved under a microscope although trial and error and a steady hand is also sufficient. During this process both fingers should not be manipulated manually unless a watch has been tampered with in the past.

Indexing work requires a lot of patience, precision and safety. At first a small safety bridge has to be removed from the movement plate and additionally an index guard might be lifted to give better visibility. Both of these parts give additional security to these vital and delicate fingers, especially the safety bridge which secures the fingers from potential damage when the caseback with stem is fitted onto the case. The easiest way to work on an Accutron is to hold it outside the case but you will somehow need to close the electric circuit. A professional 1960's Accutron testing set can be used during servicing and repairs but I can suggest mounting a small sheet of metal underneath the "grounding strap" that will hold the battery in place by connecting the negative pole (check picture above).

The 214 was the longest produced Accutron ever from 1960 until 1977. Many of the standard 214's have become very popular in the last two decades with so called conversions - an easy and affordable process of removing the dial and inserting a spacer ring and crystal with white marks printed on the inside. They are not that collectible but give a fair outcome at minimum expense. Special one-off machine conversions are also made by enthusiasts. Hopefully the beauty of the Accutron movement will never allow this breakthrough technology to be forgotten. The microscopic technology behind the success of the Accutron was so demanding that Bulova held the know-how for years and even produced index wheels for the ESA9162. But despite worldwide patents the Soviets managed to create a perfect copy of the 214 in orange - Slava Transistor. Legend has it that Nikita Khruschev was given a 214 during his visit to the USA and upon arrival to the USSR he ordered that Soviet engineers should produce an identical watch to show that Russian engineering is capable of such challenges. A batch of 1000 watches are said to be made and are extremely hard to find nowadays reaching 500$ for a dead piece. Bulova parts should be interchangeable but I guess nobody has tried... yet.

A short Accutron revival reappeared in 2010 when Bulova under Citizen ownership created a 50th anniversary edition of the 214 Spaceview. Only 1000 anniversary watches were made at 4000$ per piece but no information is available whether they contain NOS parts or were produced completely new. Pretty expensive considering that a NOS 214 can be found for a lot less :)

Keywords: bulova accutron, bulova 214, spaceview

Market value: 150-450$ (condition, box)